PROTEK CURING 200

It is a hydrocarbon resin-based, transparent amber-yellow colored, solvent-based liquid curing material that prevents rapid water loss in concrete. It reduces shrinkage cracks on the surface by preventing the evaporation of water in fresh concrete with the film layer it creates.

It provides an increase in concrete strength.

- It prevents shrinkage cracks on the surface of the concrete caused by rapid drying during curing.

- Water repellent feature

- It is more effective than laborious curing methods such as laying on sacks and canvas or watering.

- It provides more effective curing than paraffin and acrylic based curing materials.

- Indoors and outdoors,

- On all vertical and horizontal concrete surfaces,

- After fresh concrete and surface hardener applications,

- In concrete applications where air flow and evaporation are high and humidity is low,

- On surfaces that will later be coated with paint, ceramic, epoxy, etc.,

- In airports and field concretes,

- In concrete roads and bridges,

- In canals and dams,

- It is used in retaining walls.

Surface Preparation

It is applied directly onto fresh concrete or surface hardeners applied to fresh concrete using brush, roller or pressurized spray equipment. However, in order not to damage the surface, the concrete had to be set sufficiently.r

APPLICATION

In molded applications, it should be applied on fresh concrete immediately after removing the molds, before the formation of joints, by spraying as soon as the surface begins to lose its initial shine (when the surface water begins to evaporate) or by brush or roller so that there is no accumulation on the surface.

- A soft short bristle brush can be used on the wall, and a soft brush or roller can be used on the floor.

- The product is applied to the surface as a thin layer of equal thickness.

- After application, the surface gains a semi-matte appearance.

- The drying time of the material is approximately 40 minutes (+20°C).

Appearance | Transparent amber-yellow liquid |

Post-Application Appearance | Smooth, transparent film |

Liquid Density | -0.90 kg\lt(20 °C) |

Drying Time | 40 minutes (ASTM C 309) |

Flash Point | +80 °C |

CONSUMPTION

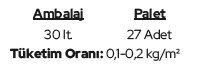

150 - 180 g/m2 (Varies depending on the absorbency and roughness of the surface.)

PACKAGING

In 30 kg plastic drums

Shelf life:

It can be stored for 12 months in its unopened package, in a closed place where it is not too hot. Shake before use.

THINGS TO PAY ATTENTION

As with all chemical products, contact with food products, skin, eyes and mouth should not be avoided during use and storage. During application, work clothes, protective gloves, glasses and masks in accordance with occupational and worker health rules should be used. If swallowed by accident, consult a doctor. In case of contact with skin, wash with plenty of water. Do not approach with open flame and do not smoke during application. Only work in areas with adequate ventilation. Do not leave the packaging lid open. It should be stored in places inaccessible to children.

SITUATIONS TO BE CONSIDERED

Application should not be made when it is raining or when there is a possibility of rain. It should be protected from frost, sun and strong wind for the first 24 hours after application. The application should be made to the part of the structure that comes into contact with water. Since the material will cure slower in cold weather, it should be ensured that the first layer is completely dry before applying the second layer. It is necessary to pay attention to the application temperature and apply within the temperature range of +5°C +35°C.