A 420 CARBON KY 2 K

It is a two-component, solvent-free resin-based, thixotropic, specially developed carbon fabric adhesive. It has high fiber saturation ability and adherence. It can be worked on vertical surfaces without leaking.

![]() Download pdf document

Download pdf document

- For bonding carbon fiber reinforcement fabrics

- In the repair and bonding of all kinds of materials such as concrete, stone and marble.

Surface Preparations

The application surface must be dry and free from all kinds of dust, dirt, weak and loose particles, cement slurry residues, oil and grease. The concrete subfloor must be strong and have sufficient compressive strength (at least 25N/mm²) and tensile strength (at least 1.5N/mm²). Damaged and weak parts should be repaired with EM 300 MORTAR and a smooth ground should be created.

Preparation of the Mixture

The product is two-component and it is recommended to mix the amount to be consumed, taking into account the pot life of the mixture. Excessive mixtures will become unusable after the potlife period ends. After component B is added to component A, it should be mixed with a low-speed electric mixer for 2-3 minutes until a homogeneous color is obtained.

APPLICATION

While mixing and applying, use rubber gloves and goggles to protect your skin and eyes from being affected. Do not add any foreign substances or water into the product. Since the product will harden immediately when mixed in extremely hot weather, the mixture should be made in sufficient quantities to be consumed. It should not be applied if the temperature is below +5ºc. Carbon fiber is cut and made ready as needed. A 420 CARBOK KY 2K epoxy resin is applied to the concrete surface with a spatula or roller. Carbon fiber is glued onto the a 420 CARBOK KY 2K applied to the surface by hand, leaving no air gap. While performing this process, the underlying epoxy resin is removed from the carbon fiber with a serrated roller. The same process is applied to the entire surface so that the epoxy resin reaches the upper surface homogeneously. If epoxy resin is insufficient, A 420 CARBOK KY 2K epoxy resin is drawn onto the upper surface again and the carbon fiber fabric is saturated with resin. If it is desired to plaster on the application whose reinforcement process has been completed, silica sand is sprinkled on the finished surface and the surface is made suitable for plaster application.

CONSUMPTION

For 300gr/m² it is 1-1.5 kg\m².

PACKAGING AND STORAGE

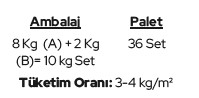

In 8 Kg + 2 Kg Metal Buckets

It can be stored for a minimum of 12 months in its unopened original buckets, in dry environments at temperatures between 5ºC and 25ºC.

SECURITY PRECAUTIONS

During the application, flammable, flammable and flammable products should be kept away, smoking should not be avoided, and care should be taken to ensure constant ventilation of the application area. Protective equipment such as glasses and gloves should be used during application.

FEATURES | VALUES |

Colour | Grey |

Intensity | 1.25±0.05 c/cm³ |

Soil Fluidity to be Applied | (+5 ºC)-(+35 ºC) |

Mixing ratio | 4:1 |

Pot Life | 30 MIN |

Solid Matter | %100 |

Adhesion to Concrete | >3 N/mm² |

Adhesion to Steel | >3.5 N/mm² |

Compressive Strength | 80 N/mm² |

Flexural Strength | 40 N/mm² |

Tensile Strength | 30 MPa |

Reaching Full Strength Meter | 7 days |

- It is a very easy material to apply.

- Water and gas impermeable

- For manual feeding

- It is used on vertical and overhead surfaces.

- It is resistant to chemicals and abrasion.

- It adheres perfectly to concrete.

- It has high mechanical properties.

- Does not require primer.

- Does not contain solvents