PROTECT-A 015 CRYSTALLIZED 1 K

PROTECT-A 015 CRYSTALLIZED 1 K

Cement-based, single-component, crystallized waterproofing mortar that is resistant to negative and positive water pressure and can be transferred to the capillary spaces of cement-based surfaces.

It is used as an insulation material in the interior and exterior of all buildings, especially foundation and basement walls, water tanks and swimming pools.

Roller, brush and trowel. Application tools should be cleaned with water immediately after use.

Consumption

4kg/m² (for 2 mm application thickness)

Application Tools:

Roller, brush and trowel. Application tools should be cleaned with water immediately after use.

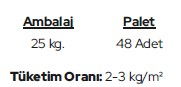

PACKAGING :

25kg kraft bag

Storage And Shelf Life:

The shelf life is 1 year from the date of production when stored in its original package, in ventilated, dry and protected environments at +5°C / +30°C, protected from sun, rain and frost.

• Packages should be tightly closed when not in use.

• Clumped or petrified products should never be used.

Attention:

During application, protective gloves and glasses should be used. In case of contact with skin, wash with plenty of water, and in case of contact with eyes or if swallowed, seek medical advice.

APPLICATION

• For each layer, 25 kg of PROTECT-A 015 WATERPROOFING MORTAR should be added to 9-10 liters of clean water and mixed with a low-speed mixer for approximately 2-3 minutes until it reaches a homogeneous consistency.

PROTECT-A 015 WATERPROOFING MORTAR should be applied to the entire surface in at least 2 layers using a brush or trowel. The application of each layer should be done perpendicular to the previous one.

• At least 7 hours should be waited between coats.

• If the following coat application occurs 14 hours or more after the previous coat application, the surface should be moistened again before application.

• The existing surface must be clean, moist, smooth and solid. The surface must be free from effects that will worsen the performance of PROTECT-A 015 WATERPROOFING MORTAR.

• Dust, lime, paint residues, mold oils, etc. The application surface should be cleaned with a wire brush.

Uneven surfaces should be repaired with appropriate surface repair materials.

Very porous surfaces such as exposed concrete and cement-based plaster should be wetted with clean water and waited until the water layer disappears, leaving the surface moist.