PROTEK VARNISH 100 BC

PROTEK VARNISH 100 BC is a solvent-based acrylic resin based curing and protection material used to cure the concrete after all fresh concrete and concrete surface hardener applications and to prevent dusting by obtaining an insulated layer on the concrete.

- It is single component and ready to use.

- The strength of concrete cured with PROTEK VARNISH 100 BC is higher than normal concrete.

- It prevents cracks that may occur during curing of concrete.

- Prevents dust formation on the concrete surface.

- Increases the abrasion resistance of concrete.

- Surface color change

- It is multi-purpose. By curing and insulating the film layer obtained in the concrete, dust formation is prevented and the concrete surface is protected, increasing its permanence.

- It is used indoors and outdoors.

- V. is durable.

- It has water repellent properties.

- Provides water impermeability.

- Increases the resistance of concrete against chlorine.

- It can be applied to the hardened old concrete surface in one or more layers at certain intervals to maintain the concrete strength, prevent dusting and obtain a shine on the surface.

- On all vertical and horizontal concrete surfaces.

- Industrial

- In reinforced concrete slabs.

- Parking lots, warehouse

- As a curing and polishing agent on imprinted concrete systems.

Application for curing and protective layer purposes on fresh concrete; after the application of concrete and surface hardener, when the concrete surface has set enough to not be damaged or immediately after the removal of the molds, before the formation of joints.

Application on old concrete for dust prevention and protective layer purposes; After the concrete surface is thoroughly cleaned of dust and other substances, the material is applied to the dry surface. The material is applied by brush, roller or spraying.

- In brush or roller applications, the concrete must be sufficiently set to avoid damaging the concrete surface.

- After outdoor applications, the concrete surface should be protected from external factors such as rain for 2-3 hours.

- The second layer is applied 24 hours after the first layer.

- After application, the drying time of the material is 60 minutes at 20°C.

- After the material is applied, the surface may darken slightly, but after a certain period of time the surface returns to its original color.

APPLICATION CONDITIONS

- Application should not be made on lightweight concrete blocks, porous walls with dense air bubbles and floor coverings.

- If it is to be applied on previously applied floor covering, the floor covering is completely removed and a solid floor is obtained.

- Do not apply to glass or similar surfaces.

- The brightness of regularly wiped material decreases over time.

- Harmful to health in contact with skin

- Do not apply in frosty or frost-risk weather.

- Protect the applied surface from rain, frost, pedestrian traffic and high humidity until it is completely dry.

- Do not apply in conditions where the surface and ambient temperature is lower than +5°C and higher than +35°C.

- Protect the surface from heavy traffic for 24 hours after application.

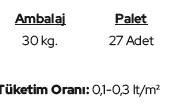

20 liter metal cans and 200 liter barrels

Storage And Shelf Life

Since it is flammable, it should be kept away from fire and hot environments. When stored in its original package at +5°C / +25°C in dry, protected and ventilated environments, protected from frost and direct sunlight, its shelf life is 1 year.

Attention:

During application, protective gloves and glasses should be used.

CONSUMPTION:

Depending on the absorbency of the concrete surface and the ambient temperature;

0.300 - 0.400 lt / m² (2 layers)

- Material Structure: Acid and solvent based, transparent

- Density 88± %2 g\ cm3

- Flash Point 88°C

- Surface Temperature to be Applied (+5°C) – (+35°C)

- Drying Time (20°C) 45-60 minutes