PROTEK TH 100 SLV

PROTECT TH 100 SLVIt is a self-leveling, single-component, polymer-modified, cement-based floor leveling mortar that is used as a leveling mortar on concrete floors that are not as flat as desired, with a thickness of 5-20 mm at a time.

- It spreads spontaneously.

- No shrinkage or cracking occurs.

- Underfloor heated floors

- It is used indoors and outdoors.

- Fast hardening feature

- It is resistant to frost.

- It can be opened to pedestrian traffic within 3-5 hours after application and to normal traffic within 24 hours.

PROTECT TH 100 SLV is used for leveling and removing irregularities of rough and rough concrete surfaces; in precast concrete surface leveling; It is used for surface leveling before the application of flooring materials such as carpet, ceramic, marble, natural stone, parquet, vinyl and PVC.

Surface Preparation

The application surface must be cleaned and free of oil, paint, dust and free substances. Humidity coming from below the surface should be prevented. The concrete to be applied must be at least 14 days old and have the structural strength to withstand the load. Cracks on the concrete surface should be repaired with mortar and the adherence enhancer PROTECT TH 100 SLV should be used to ensure that this repair mortar adheres well to the surface. On surfaces with underfloor heating, the heating system must be activated 10 days in advance and the heating system must be turned off during application. The heating system can be operated approximately 72 hours after application.

APPLICATION

- The prepared mixture is spread on the surface and the desired thickness is achieved with a trowel or rubber broom.

- In order to obtain a monolithic and smooth surface coating, uninterrupted application is required.

- Air on the surface must be removed with a hedgehog roller.

- During the curing of the newly applied screed, precautions should be taken against high temperatures, direct sunlight and wind to prevent it from drying too quickly.

- Vapor permeable materials such as ceramics can be coated on the screed 8 hours after application.

- For coating materials that are not vapor permeable, such as PVC coating, at least 3 days should be waited and the moisture content should be measured.

- Coating materials to be applied on PROTECT TH 100 SLV should be brought to the application area and stored 3-5 days in advance and their compliance with the environmental conditions should be ensured.

TECHNICAL DATA |

|

Rate of water to be added | % 20 (powder product) |

Rupture strength | ≥ 1 N/mm² |

Application temperature | +5°C / +35°C |

Pan life | 5 - 15 minutes |

Start of socket | 1 hour (20°C) |

socket end | 4 hours (20°C) |

Mechanical strengths |

28 days |

Pressure N/mm² |

> 35 |

Flexural N/mm² | 7 |

Brush and Trowel

Application tools should be cleaned immediately with water after use.

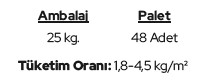

20 Kg. Kraft Bag

Shelf life is 1 year from the date of production when stored in its original packaging, in ventilated, dry and protected environments at +10°C/+30°C, protected from sun, rain and frost.

Attention:

During application, protective gloves and glasses should be used.