PROTEK GH 400 T

PROTEK GH 400 T Single Component, Non-Shrinkage, High Strength, Cement Based, Ready to Use, Flowable Grout Mortar

- Flowability and consistency can be adjusted

- It gains strength very quickly and can be opened to traffic after 1 hour.

- Since it does not cause shrinkage, its usage area is wide.

- Does not decompose and does not bleed water

- Their final strength is high.

- It is resistant to various chemicals, oils and acids.

- It is resistant to impacts and vibrations.

APPLICATION METHOD:

The surface must be solid, dust-free, dry, clean and have sufficient load resistance. The surface should be cleaned of dust by sweeping. Regional defects, if any, should be repaired with repair mortars.

APPLICATION

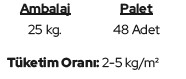

3-4 liters of clean, clear water at normal ambient temperature is placed in a clean container that is free of any substances that prevent mixing and adhesion. Powdered in a container filled with water and in a 25 kg bag PROTEK GH 400 T GROUT is emptied. It is mixed with a low speed mixer until a homogeneous mixture without lumps is obtained. The mortar obtained at the end of the process is quickly placed in place. After the material reacts, it should not be mixed again by adding water. To fill the bottom of the gaps that are surrounded on four sides and covered. PROTEK GH 400 T GROUT It should be poured from one side. It prevents the formation of cavities and accelerates fluidity by expelling air by skewering from one side.

Döküm kalınlığı bir seferde, tabaka kalınlığı olarak 10-50 mm arasında olmalıdır. Silindir şeklindeki küçük çaplı ankajların doldurulmasında ön bir deneme yapılması tavsiye edilir. 50 mm’den kalın uygulamada malzemenin %30’u oranında, yaklaşık 5-12 mm çaplı agrega ilavesi yapılabilir.

2.2 Kg/m² (for 1 m³ application thickness)

CLEANING THE TOOLS

After application, the tools and equipment used should be cleaned with water. After the hardened mortar freezes, it can only be cleaned by mechanical methods.

STORAGE AND SHELF LIFE

When stored in its original package at +5ºC / +30ºC in ventilated, dry and protected environments, protected from sun, rain and frost, its shelf life is 1 year from the date of production.

The mouth of the containers should be tightly closed when not in use.

Lumpy or petrified products should never be used.

ATTENTION

During application, protective gloves and personal care should be used. In case of contact with skin, wash with plenty of water, and in case of contact with eyes or if swallowed, seek medical advice.