PB 018 2K

PROTECT-A PB 018 2K

It is a two-component, polyurethane-bitumen modified, liquid water insulation material. It cures quickly and adheres perfectly to various surfaces, forming a highly elastic film.

Features:

It adheres perfectly to all types of surfaces.

No thinning required.

Excellent mechanical properties, high tensile, stretch, tear and wear

provides resistance.

It shows good chemical resistance.

It is effective in water vapor transmission. The film breathes and thus moisture is kept under the floor.

prevents accumulation.

It allows the application of thick coats and does not cause bubbles.

Provides high crack bridging.

It has excellent coverage and adheres to the surface very well.

It is easy and fast to apply and offers easy solutions in detail insulation applications.

It has high thermal resistance and can be used between +80 °C and 200 °C.

The applied film maintains its flexibility up to – 40 °C.

The 1/1 volume of the ingredients makes mixing easier.

It cures fast.

Its crack bridging property is excellent.

It adheres perfectly to almost all types of surfaces, with or without a primer.

Although it does not need to be diluted, solvent can be used depending on the conditions.

Thermal resistance is excellent; The product never softens.

Maximum usage temperature is 80 oC, maximum shock temperature is 200 oC.

It is resistant to cold. The film maintains its elasticity down to -40°C.

It has excellent mechanical properties; extensibility, tensile, tear and

It has high abrasion resistance.

It has good resistance to chemicals.

It functions effectively as a water vapor barrier.

Since it is a liquid material, it is applied with a roller; during application (torch)

It is not necessary to use an open flame.

NİTELİK (23 oC, %55 R.H.) TANIM

Component A: Resin 1300 ± 50

Component B: Asphalt derived mixture 4250 ± 50

Density (g/cm3)

Component A: Resin 0.85±0.05

Component B: Asphalt derived mixture 1.2±0.05

Viscosity of the mixture (Brookfield, mPas) 3000

Density of the mixture (g/cm3) 0.97

Pot Life (minutes) 20-30

(using 100g (A+B))

Flash Point (°C) > 40

Drying Time (hours) 12

Recoating Time (hours) 12-24

Service Temperature (°C) -40 to 80

Maximum Short-Term Exposure Temperature (°C) 150

Hardness (Shore A) 35

Tensile Strength at Break (N/mm2) >2

Elongation (%) >1500

Tear Resistance (N/mm²) 20-22

For waterproofing purposes;

In roof terrace areas,

In parking lots,

In aircraft hangars,

In tunnels,

On asphalt and EPDM membranes,

In plant beds and green roof systems,

Insulation of roofs made of metal or fiber cement,

In potable water tanks,

Insulation of foundation and curtain concrete of constructions,

It is used in irrigation channels.

Surface Preparation

The existing surface is clean, dry, flat and free of dirt, dust, oil, wax, mold and PROTECT-A PB 018

The surface must be free from effects that will worsen 2K performance.

All kinds of loose, dusty, cracked, crusted and previously painted surfaces

scraping, sanding, wire brushing and/or machine assistance (pressurized

must be cleaned with water spray or sandblasting).

At least 1500 – for washing existing exterior surfaces with pressurized water.

There should be 2000 psi water pressure.

For metal roof surfaces, loose rust, milling, rust formations adhering to the surface

or white rust on the metal surface using the methods mentioned above.

They should be removed from the surface.

Damaged or decomposed surfaces must be repaired.

Old painted surfaces and irregularities should be sanded.

After the repair, depending on the surface condition, epoxy or polyurethane based coating is applied.

After priming with a suitable primer, liquid membrane application can be started.

must be passed. The surfaces to be applied must meet at least the following standards:

should be:

Hardness: R28 = 15 Mpa

Temperature: 5 – 35 o C

Relative Humidity: < 85%

APPLICATION:

Components A and B of the product are mixed separately with predetermined mixing ratios.

Supplied in packaging. Component B is completely poured into component A and

It is mixed with a mixer at 300 rpm. After the material is mixed

should be used immediately. Pot life of the product is 20 – 25 minutes at 20 °C. Prepared

The mixture is applied to the previously prepared surface with a roller, brush or spatula.

Make sure that the ground temperature is above 10oC during application.

should be done. Different primer for glossy, metal and aluminum surfaces

should be used. Minimum protection of applied surfaces (direct contact with water)

Attention should be paid 24 hours a day. Minimum consumption 1.0 depending on application base

is between 1.6 lt/m2 and 1.6 lt/m2

Post-Application Cleaning: Equipment used during application

It should be cleaned with a suitable solvent immediately after application.

Consumption:

1.0 to 1.6 lt/m2

Application Tool:

Roller, brush, suitable spray

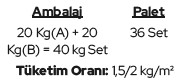

PACKAGING:

Component A (resin) 20 kg and component B (hardener) 20 kg in proportion to 40

kg sets

Shelf Life and Storage Conditions

In its unopened original packaging, in a dry environment at temperatures between 5°C and 25°C.

It can be stored for 12 months. Opened packages should be used immediately.

Attention:

The packaging of the product should be kept closed and not opened.

Products must be protected from direct sunlight and risk of freezing. Products, 5

It can be stored for 12 months in dry environments between °C and 25°C. Pallets on top of each other

should not be placed.

Contains low amounts of volatile and flammable solvents. smoking during application

It should not be consumed and should be worked in well-ventilated environments away from naked flames.

Solvents are heavier than air and therefore circulate on the ground.

It should not be forgotten that he will do During the application, comply with occupational and worker health rules.

Appropriate work clothes, protective gloves, glasses and mask should be used.

Due to the irritating effects of the uncured product, the ingredients may cause contact with the skin and eyes.

should not be contacted. In case of contact, it should be washed with plenty of water and soap.

If swallowed, consult a doctor immediately. out of reach of children

Store in places.