CER 035 2K

It is a semi-elastic waterproofing material consisting of cement-based powder component and polymer emulsion-based liquid component, which can be applied before the final coat coating material.

Product features:

It has high adhesion strength.

It is water repellent and resistant to water and frost.

It provides seamless insulation on the surfaces it is applied to.

Any kind of coating material can be applied on it.

It is semi-elastic.

It is easy to prepare and apply.

It does not contain solvents and is environmentally friendly.

Technicial Specifications:

Usage time of the prepared mixture – Pot life: Maximum 3 hours

Waiting time between coats: Minimum 6 hours

Time required for application: Minimum 3 days

Chemical Structure: Cement and polymer emulsion based waterproofing material

Mortar Density: 1.80 ± 0.01 gr/cm3

Application Thickness: 2 – 3 mm

Colour: Powder: Gray, Liquid: Milk white

In wet areas such as bathrooms, kitchens and balconies,

Waterproofing in wet areas such as terraces, ornamental pools, small volume water tanks

It is applied before the coating material.

It is used indoors and outdoors, on horizontal and vertical surfaces.

Mixing ratio:

The powder component (20 kg) and the liquid component (10 kg) must be mixed completely.

Surface Preparation:

The surface must be dry, clean, sound and free from dust, oil, dirt or adhesion.

Blocking materials should be cleaned from the surface, substances such as mortar and cement residues should be removed.

should be engraved.

Repair of surface defects with a depth of more than 1 cm should be done 6-8 hours in advance.

After surface cleaning, increasing adhesion strength and surface absorbency

To stabilize the surface, the surface should be primed in a single layer and let it dry for 1 - 2 hours.

should be left.

Before applying on exposed concrete surfaces, check the adhesion strength.

In order to increase the

should be left.

Immediately before application, wash surfaces such as concrete and cement-based plaster with clean water.

should be moistened. You should wait until the surface absorbs water, and clean the surface during application.

Care should be taken to ensure that it is moist, not wet.

APPLICATION:

Apply the mixed product to the surface at least twice, with a dry film thickness of 2 mm.

coat should be applied. After the first coat is completely dry, apply the second and other coats.

Applications should be made perpendicular to the previous application.

To ensure the continuity of the insulation, apply repair mortar to the edge and corner joints.

chamfer should be made.

Water impermeability such as edge and corner joints in cases where chamfering cannot be made

Tape should be applied in weak areas.

Depending on the characteristics of the application surface, when necessary, apply between two layers.

Application can be made by placing a net. In cases where mesh reinforcement is required, first a

A layer is applied and a net is laid on it before it dries.

Consumption

Recommended consumption amount for 2 mm film thickness; It is 3.6 kg/m2. This value is the surface and

may vary depending on environmental conditions.

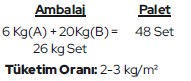

PACKAGING

20 kg bag

10 kg plastic drum

Surface and Ambient Temperature

During application, the surface and ambient temperature should be between +5°C and +35°C.

Application Recommendations:

In the coating process on insulation, the insulation material may be damaged by mechanical effects.

Care must be taken not to see it.

It should not be applied against negative water pressure.

After mixing, the product should be used within its pot life. During application

Products that have expired their container life should never be used.

During application, no foreign substances should be added into the mixture other than the components of the product.

No material should be added.

Application should not be made on unstable surfaces. Strength and durability of old surfaces

carrier status should be checked before application.

The surface should be protected from air currents during and after application and should not be washed with water.

contact should be prevented.

On surfaces that are in danger of freezing, frozen, or whose icing is melting within 24 hours

should not be applied.

Be careful not to expose the material to direct sunlight in hot weather.

should be done.

Application should not be made on hot surfaces that are extremely windy or exposed to direct sunlight.

If it is necessary to apply in these environments, the environment and surface should be examined before starting.

must be made ready for application.

Application should not be made in rainy weather, the applied surface should be cleaned for 24 hours.

should be protected from rain.